The MARIOW project is developing a robot for semi-autonomous underwater welding work. MARIOW thus presents a solution for the increasing maintenance requirements of maritime infrastructure. The welding robot uses a stereo camera system and artificial intelligence to recognise welding seams independently and plan welding work. The work is carried out by a precise modular robot arm. The aim is to relieve divers and make maintenance safer, more cost-effective and more sustainable.

Maritime infrastructure is crucial to Germany's competitiveness. Whether it's port facilities or offshore wind farms—without modern infrastructure, Germany could neither achieve its energy policy goals nor maintain its position as a leading trading nation. However, the maritime industry faces significant maintenance needs, which require innovative solutions. The MARIOW project has developed one such solution based on autonomous robotics, using the example of deteriorating sheet piles.

For many tasks, the use of underwater robots is now an industrial standard to reduce costs and increase working depth. Welding, however, is an exception because there is no robotic system with this capability available worldwide. Therefore, despite the shortage of skilled workers, the use of experienced and well-trained divers remains necessary, and the maintenance of metallic structures is associated with high costs and health risks.

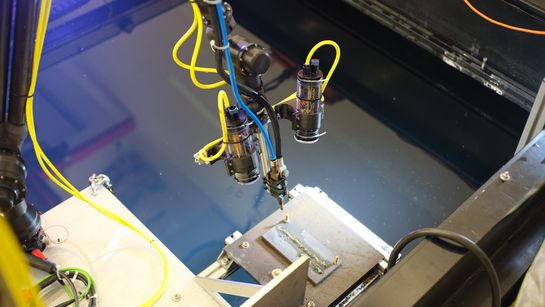

In the MARIOW project, a submersible robot has been developed that can perform welding tasks autonomously using an innovative flux-cored arc welding process for underwater. Equipped with artificial intelligence and a stereo camera system, the robot can autonomously detect the weld seam and plan the welding process.

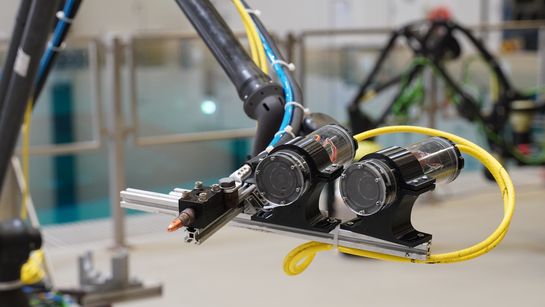

DFKI has developed a modular robotic arm to carry out the welding process. With a modular joint system, the arm can be adapted to various applications, such as for expanded mobility or a more compact design. The precise control of the robotic arm along the weld seam is achieved on two levels: 1) a decentralized control of the joints and 2) coordinated motion planning and collision avoidance for the entire system.

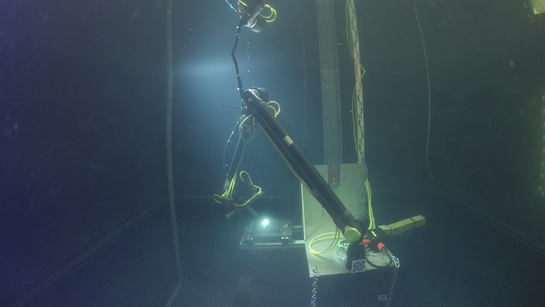

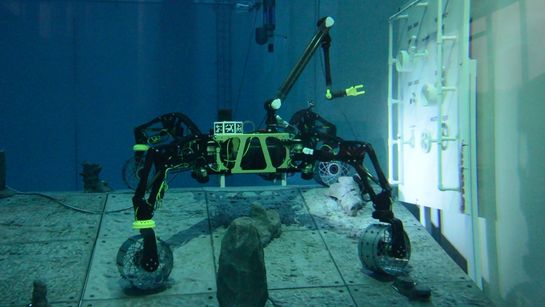

The deployment of the welding robot can be flexible: either mounted on a suitable carrier system (e.g., the crawler SherpaUW) or using a guiding and lowering system, such as on a sheet pile wall. The technology developed and demonstrated in MARIOW is designed to relieve divers from repetitive and time-consuming tasks, thus making an important contribution to the efficient maintenance of critical infrastructure.

Partners

AMT GmbH

Unterwasserkrause - Mutzeck GmbH

TH Köln Institut für Material und Prozesstechnik

TH Köln Labor für Autonome Systeme

Frauenhofer-Institut für Graphische Datenverarbeitung