Efficient processes in the face of high complexity

To increase the efficiency and to optimize the utilization of available resources in production facilities, it is necessary to quickly adapt to changing requirements, like client requests, material shortages and other deviations from the most recent plan. It is a hard task to track and analyse the complexity of processes and the amount of relevant state variables. Currently, it is not feasible to quickly produce and evaluate different courses of action by hand.

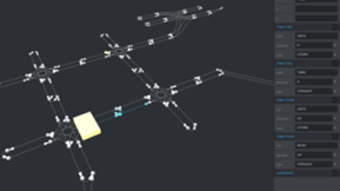

To enable a better handling of such settings, a simulated production environment is to be developed. This simulation serves the purpose to evaluate different courses of action ahead of time, taking into account the availability of required resources, the interdependencies between tasks and other relevant factors.

Automatic intralogistics in a simulated production environment

In the simulated production environment robotic agents carry out intralogistics tasks. Planning algorithms and autonomous navigation-schemes are developed, in order to establish minimal-conflict transportation and to provide the required parts for the assembly workers at the right times.

By continuously updating the state variables of the simulation according to the changes in the real production environment via a software interface, the system will be able to provide viable response behaviors to anomalies immediately. While our focus is the implementation of the simulated environment and the planning algorithms, other project partners are working on the automatic acquisition of the relevant input data simultaneously.

Innovative approach with transferability in mind

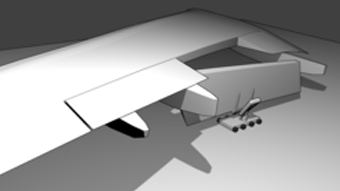

To improve the relevance and later the transferability to the shop floor, the specific tasks that make up the production process are modeled according to the real environment. In order to facilitate a long-term use and a broad applicability of the system, a focus is put on extendability and transferability.

Partners

- Airbus Operations GmbH

- Deutsches Zentrum für Luft- und Raumfahrt DLR

- GEOMETRIC Europe GmbH

- 3D.aero GmbH