Until now, underwater welding, such as repairs to port facilities, offshore structures, and other metal structures, has been carried out manually. However, demand far exceeds the number of skilled workers available. This is where the MARIOW (Maritime AI-Guided & Remote Operated Welding) project, funded by the Federal Ministry for Economic Affairs and Energy (BMWE), comes in: For the first time, the partners have developed a robotic system that can perform underwater welding work largely autonomously. In the future, it will relieve divers of physically demanding and risky tasks while producing more precise, uniform weld seams even under difficult visibility conditions.

In addition to the DFKI Robotics Innovation Center in Bremen, the project consortium included the Institute for Materials and Process Technology and the Laboratory for Autonomous Systems at TH Köln, the Fraunhofer Institute for Computer Graphics Research IGD, AMT GmbH, and Unterwasserkrause – Mutzeck GmbH.

Modular underwater manipulator

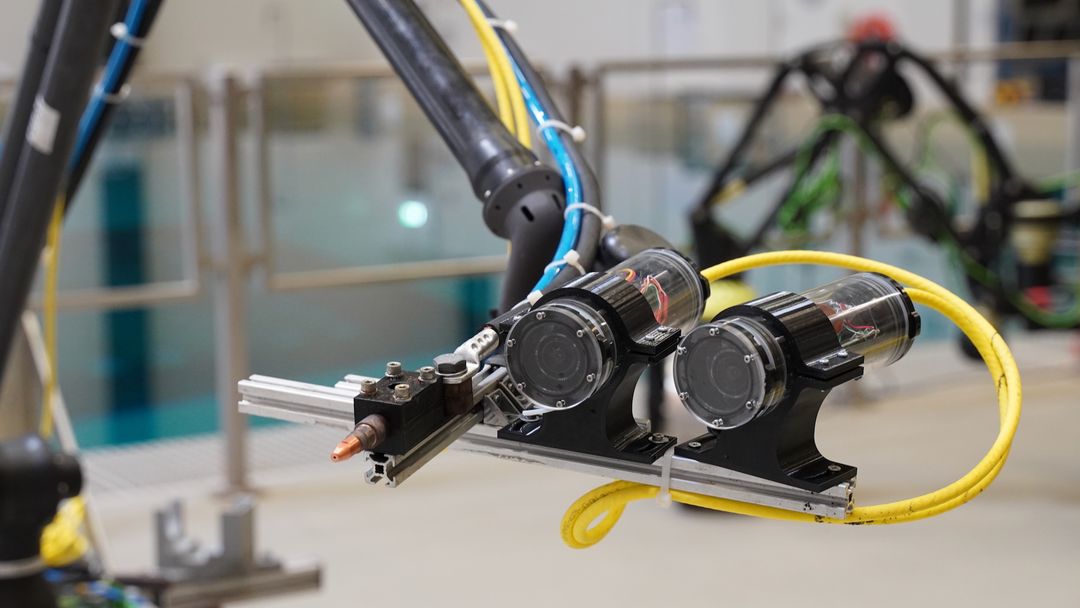

The central element of the system is a modular underwater manipulator developed at DFKI. The robot arm can be used at depths of up to 6,000 meters, has a reach of two meters, and can be flexibly adapted to different application scenarios. Thanks to a combination of decentralized joint control and higher-level motion planning, the manipulator performs welding tasks with precision and repeatability.

AI-supported determination of the welding path

Another core component of the MARIOW system is the AI-supported determination of the welding path. The stereo camera system developed by Fraunhofer IGD delivers high-resolution underwater images directly at the welding torch. Based on this, the Laboratory for Autonomous Systems at TH Köln has developed and trained AI models that autonomously recognize welding joints as well as their start and end points. The AI then calculates the optimal movement of the robot.

Innovative flux-cored wire welding process

A decisive technological advance is the flux-cored welding process, which makes underwater welding reliably automatable for the first time. The underwater flux-cored arc welding (UW-FCAW) process, developed by the Institute for Materials and Process Technology at TH Köln in collaboration with AMT GmbH, replaces conventional stick electrodes, which have to be replaced after just a few centimeters of weld seam, with a continuous wire. This uninterrupted flow of material forms the basis for stable, controlled, and reproducible seams.

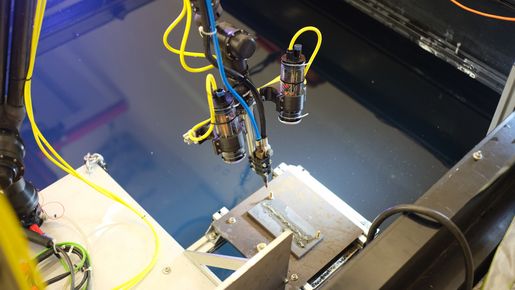

Successful final demonstration

In the final project phase, all sub-technologies were brought together in DFKI's underwater test basin in Bremen and demonstrated in a practical setting. This involved the complete AI-based determination of the welding line, the automated planning of the welding path, and the final welding using the UW-FCAW process. “We were able to successfully demonstrate that automated submerged flux-cored arc welding is feasible. We have thus laid the foundation for a globally innovative technology that holds great potential for the maritime industry and Germany as an industrial location,” says Christian Koch, project manager at the DFKI Robotics Innovation Center.

The consortium intends to build on these results in future projects. In addition to improving the quality of the weld seam, the primary focus will then be on practical application in the harbor basin. The influence of salt water, currents, and waves will then necessitate adjustments to the existing systems. In addition, the higher pressure at depth increases the requirements for components, for example, in terms of tightness. Additionally, a laser system is to be integrated to remove the slag produced during welding.